Sometimes you know what you want in a PCB of a product when you design it. Other times, though, the PCB does not give you a clue of what should go in there unless you get involved from the beginning with its design.

This is the case with many electronic PCB product designs. Lets look at some common pains in creating great electronic products from the point of view of:

- Individual Designer

- Professional

- Organization

Building the design with the right components and standards:

Choosing components and creating a design for your PCB is not an easy task. Making the wrong choice in selecting components leads to challenges like expensive manufacturing. It also leads to high lead times for supply chain and creates a communication problem when doing verification of those components. The pain while building components for PCB design is both experienced by the customer and by the manufacturer.

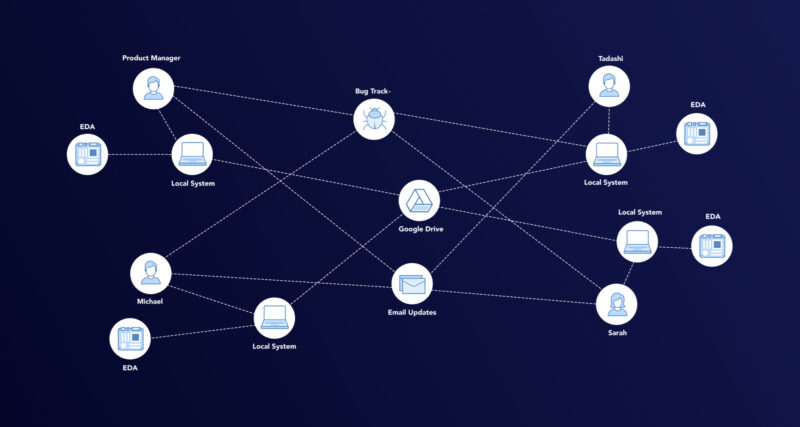

Stakeholder Collaboration and Feedback:

Whether you’re discussing design decisions, crediting components, or the nuances of responsive deliverables—there is no question that you need feedback in all that. The changing demands of PCB stakeholders require PCB designers to juggle many conflicting tasks and roles. Understanding the process of cross communication with the people you need to have involved in your design process is very important. A lot of the times the way to get feedback in the process of building from prototype to production is so tedious and nerve wrecking that it creates so many blockers. Even if you are an individual designer you still have to get it reviewed to share your designs with other people.

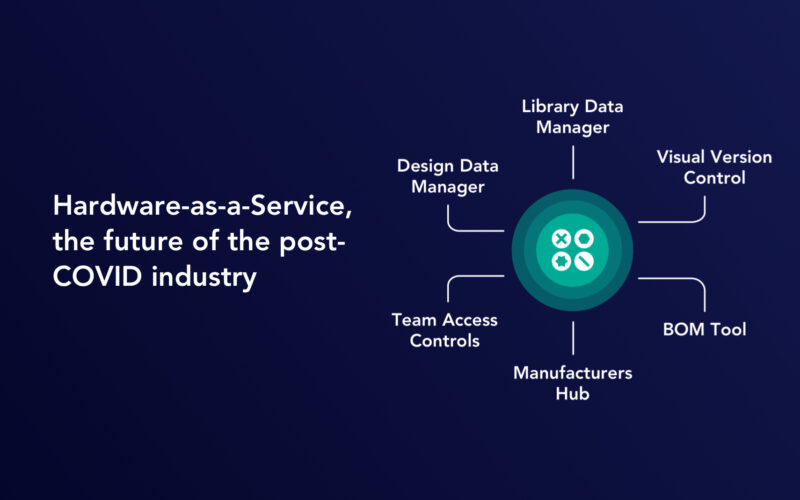

Data Management:

Let’s face it, we are all overwhelmed by information – so much so that we get data fatigue. With thousands of hours invested in the design and production of PCBs, the need for a streamlined approach to managing all of those design data is imperative. There can be multiple versions of designs, component libraries, bill of materials and data related to manufacturing. Knowing what version to look at needs the right set of tools. Data handled manually goes astray. Who hasn’t lost a set of files or been sent incorrect data?. You have ever-changing company requirements that are often delivered at the last minute, the pressure is on to meet deadlines without errors, and it seems like no matter what you do or how well things are organized there is always data miss management.

Manufacturing:

If you’re a PCB designer, chances are you’ve spent countless hours creating pcb designs for yourself or your business, only to find that your project had too many errors with manufacturing to finish in time. Not to mention that amidst the pressure of deadlines and tight budgets, your designs are bound to be riddled with mistakes. The more parts that you have made the higher the chance for an error and this is where manufacturers need to be notified as soon as possible in case of issues.

Processes have to change, companies grow a lot, and what worked a year ago may no longer be working. Above all, it’s about finding what works well for yourself and people around you while constantly improving along the way.

Checkout how https://inventhub.io can help you in your PCB design process when building a product.