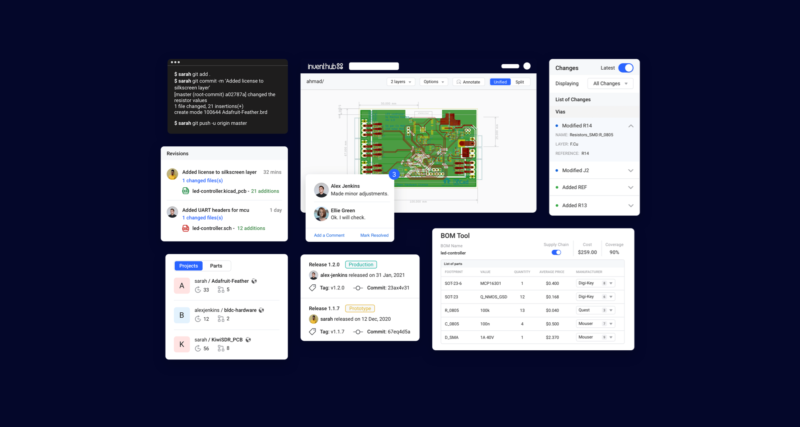

Electronic product development process is complex – even with modern tools. Integrated development environments are now available that provide automated circuit generation, simulation, bill of material generations, and debugging, all within an integrated application. The integration of design with architecture while implementing complex requirements, integration of vendors and suppliers, component or module availability, make it very difficult to define the implementation of the process in a cost-effective and streamlined way. Large percentage of initial implementations is rework, caused by poor project management or due to wrong requirement fulfillment and verification procedures. The existence of many separate sub-processes like schematic capture, pcb fabrication, placement and routing, simulation, data security management makes the problem in the whole process even more visible and deeper.

Are you aware of modern electronics product development processes? Do people talk how you’re developing electronic hardware? There are plenty of successful hardware products out there. Why should we change something that works well? Because making a real electronics product is not just about making a running prototype or having a printed circuit board (PCB). It’s not enough to build your electronic product successfully while meeting the time to market. The whole story starts with selecting your components: choosing appropriate ICs to meet your requirements, understanding part datasheets, supplier timelines, and your process of iteration with the stakeholders involved.

Let’s look at some criteria’s to consider when modernizing your electronics hardware development process.

Modern tooling:

The smallest change can make the biggest difference in developing electronics. When looking at modern tooling it should involve all the electronics product design resources — people, tools, design data, component libraries, bill of materials, manufacturing.

Process Experience:

Something that is part of your workflow has to be plug and play, intuitive and connected. A great experience matters at every step of the electronics hardware development process. This is where centralization of resources is required with a tool to perform design reviews, gather feedback and track work progress in real time which leads to a better product development process to produce products faster and with a high standard of quality.

Total Cost of Ownership:

This is very important as hidden costs can add up. There might be functional tools for every step of the electronics hardware development process. If the process is not centralized and you have to have multiple systems or multiple diverged processes to bring your product to life then cost is increased and the time to finish is delayed.

Getting the right support:

Understanding the availability of a step of the process can help in cost efficiency and speed. At times there might be blockers and some parts of the process might have problems. This is where the right kind of support can be helpful from various stakeholders involved inside or outside the process.

Staying up to date:

Transparency in the process of creating an electronic product is crucial. It important to have a stream of updates that helps in early communication and insights on how far the product is from completion.

Ecosystem:

Involving more functional integrations into the process that help in asynchronous workflow management and collaboration creates opportunities to optimize the process. The integrations might be an automated real time sync between bill of materials and supplier data. Developing an ecosystem around your process provides a value in terms of quality of your electronics product.

Intellectual property, Security and Reliability:

When there are processes owned by outside stakeholders and not under one roof then there are often conflicts with non-disclosure agreements and ownership of the electronics data. With regards to digital and in a way centralized tooling helps in tackling IPs, security and the reliability of the data.

Check out how https://inventhub.io can help you in your electronics hardware product development.