We’ve talked extensively about the importance of efficient collaborative tools in the hardware industry. To summarize, these tools minimize communication gaps and miscommunication, and bring all the stakeholders together on one platform, leading to more efficient multi-stakeholder collaboration strategies, design principles and best practices.

This is particularly necessary for the hardware industry, due to the complex processes numerous stakeholders involved. These factors create a number of communication and workflow hurdles which cannot be overcome by conventional methods.

Generally, collaborative tools have become the go-to solution for effective communication, workflows, and planning. These tools come with an array of features, which differ depending on the software. However, not all of these features may be suited to the hardware industry, and major requirements may be missed.

Therefore, it is imperative to note what features a tool is offering and ensure that they fit the rigorous requirements of the hardware industry.

What are the key features required?

There are a number of key components which are necessary for a collaborative tool specific to the hardware industry. The ones which are absolutely essential for streamlined hardware product workflows are:

Change management

Any hardware-oriented collaborative tool worth its salt must have efficient change management. This means that users must be able to alter product designs without hampering the work of the rest of the contributors and adding unnecessary challenges.

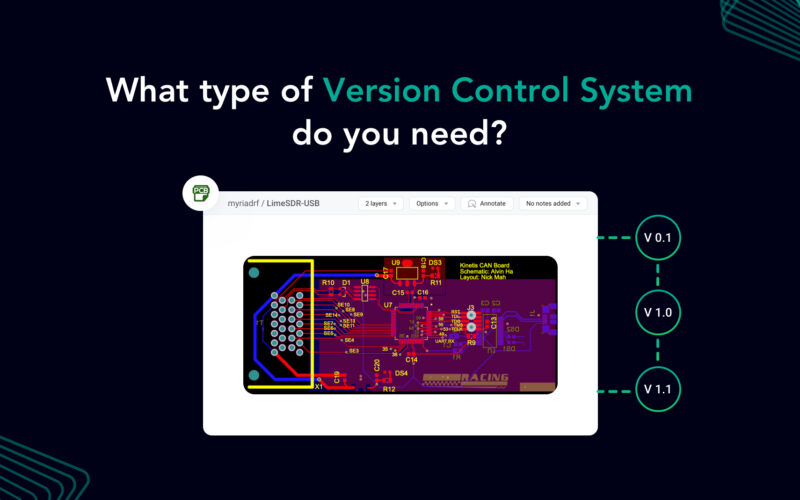

Version Control

Version control is an essential feature, and creates a strong base of change management. This is because users can make changes in new branches of the main product design, and then incorporate them into the Master branch.

All of this takes place without affecting what other users are doing to the same product, but still keeps them in the loop about what goes on.

Revision Control

Especially in the case of corporations, it might not be deemed appropriate for all stakeholders to be able to make changes in a product design. After all, not just engineers and manufacturers, but marketers, suppliers, and distributors are also part of the product life cycle.

Those members who do not have the technical know-how or authority must not be allowed to make changes in the designs. To prevent any changes from being accidentally made, revision control is necessary. It enables administrators to assign what level of access each user can have, and whether they can make changes to the files or just view them.

Visual differencing

Visual differencing, aka visual diffing, refers to being able to clearly see what changes have been made to a product design. With this feature, users can clearly identify the changes due to color-coded schematic views of the files, with deletions and insertions easy to point out.

Annotations

Often, just looking at what has been changed in a design may not be enough for the rest of the users, and they may have feedback as well. Therefore, it is important to have a feature which allows members to comment on various aspects of the product design, and give their feedback about what changes are required etc.

In conclusion, when looking for the best collaborative tool for a hardware company, the abovementioned features must be there. These will smoothen the workflow and make the product life cycle efficient.