Hardware design and production in the current era is no longer restricted to one location, with all the parties involved interacting in one place. Now, numerous parties are involved at every step of the way, and they all have their own feedback and roles. This leads to communication gaps and large chunks of time dedicated to various communication methods, leaving the engineers with little wiggle room for cutting-edge innovation.

In most cases, teams rely on old-school methods such as email, phone calls, and face-to-face interaction for collaboration. This is quite inefficient, as it isn’t easy to keep track of what needs to be done. Resultantly, there can be misunderstandings, leading to hurdles in the design and manufacturing operations.

As of now, there is no standard tool for collaboration in the hardware industry. Each company utilizes certain combinations of tools, or in the case of larger organizations, creates collaborative tools of their own. Whenever hardware designers switch jobs, they have to relearn an array of communication methods which their respective companies use. This means that a lot of time is taken up in tasks which are not essential to their roles.

In addition, due to a dearth of good tools, there is very little long-term planning which takes place in the industry. This means that wires often get crossed, leading to conflicting priorities and misunderstandings. This also creates a lack of transparency, where all stakeholders are not in the loop with where things stand, leading to an element of mistrust and no room for innovation.

There is an array of tools out there making remote work and collaboration quite convenient across a number of sectors. However, with an industry as technical as hardware design, simple communication tools like Slack or Asana will not work. There is an extensive list of requirements involved, with the major ones being:

- Real-time collaboration: The tool must allow users to make changes in real time, and for others to respond to them accordingly and swiftly.

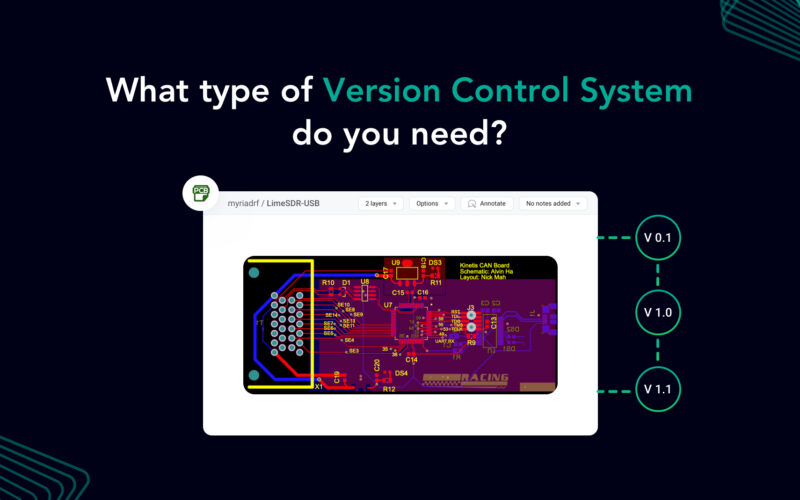

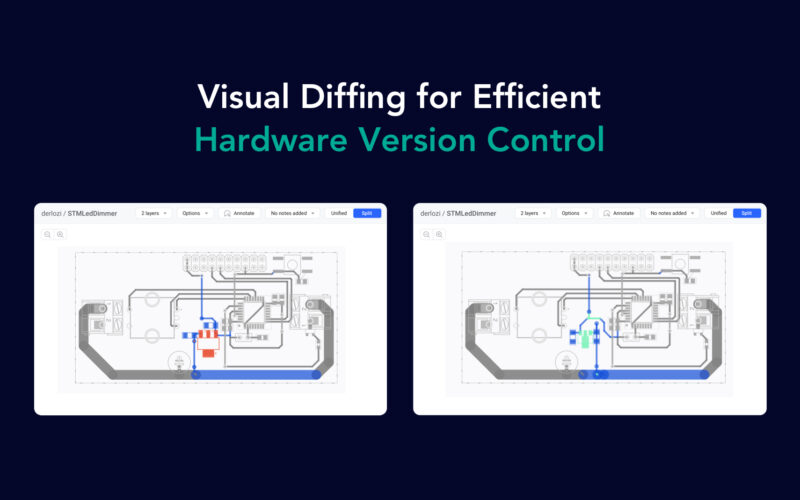

- Version control: Users must be able to control the changes made in the product, and compare how different versions measure up to each other.

- Efficient communication: Users must be able to communicate with each other, and discuss any changes or revisions made easily.

- Visual difference comparison: As a highly technical field, there are a layers and layers of visuals involved in hardware design. Users must be able to see these components visually, without the whole thing being a confusing jumble.

Currently, most of the tools available in the market offer various combinations of these features, but a tool that utilizes all of these is almost non-existent. The rare solutions that do exist are prohibitively expensive, with subscriptions going up to thousands of dollars per year. This automatically prevents a large number of hardware companies from employing them. That holy grail of a tool, which offers all the above features, and is affordable, is sure to revolutionize the industry. It will give designers and engineers the breathing space they need to innovate and create, while ensuring that all other stakeholders know what is going on and are comfortable with the process. This will elevate the hardware industry to new heights, and allow it to flourish as it should.