This past year, it has become clearly apparent that the way workplaces function have changed immensely. Before this, remote work was largely a concept where team members of a company or its various stakeholders were scattered across the world. For example, the suppliers may be in Kenya, the manufacturers in China, the engineers and designers in Japan, and the clients in the USA. Most industries have already become globalized, with team members collaborating with each other across continents.

With COVID-19, this concept became a global phenomenon, as this pandemic made workplaces all over the world close their offices and have their staff work from home for months at end. This has been the case for the hardware industry as well, which is a complex field with numerous stakeholders involved. In addition, many of the stakeholders do not have the extent of technical know-how which the engineers and designers themselves may have. Therefore, explaining any new product or changes to a product in progress is a complicated task, with multiple hurdles in the way.

Furthermore, things become even more complex due to the deadlines involved, with numerous engineers and stakeholders working to get a product out in good time. There is a definite need for efficient, quick, and comprehensive collaboration across the board.

What do we mean by real-time collaboration?

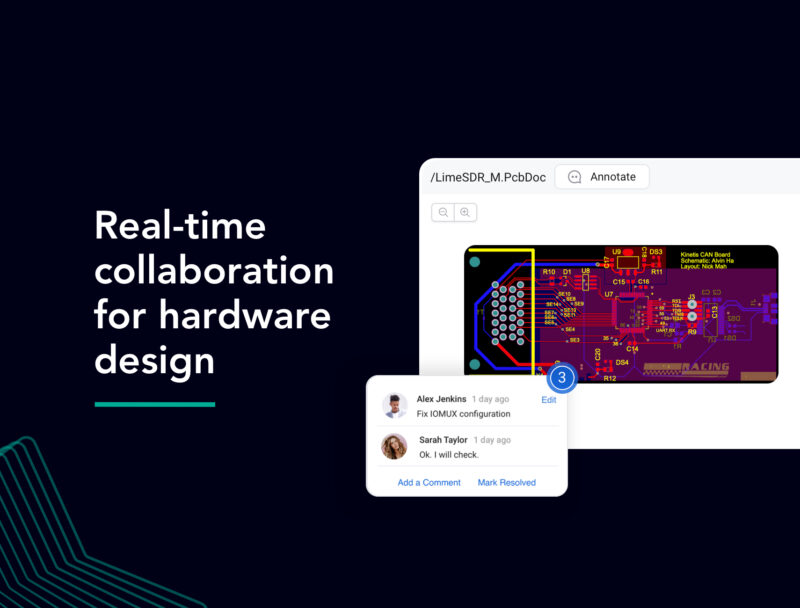

Real-time collaboration means that all the stakeholders are in the loop about what is going on in a product’s life cycle, and are able to respond to any changes or requirements immediately. This requires all collaborators to be notified of changes as they are made, be able to identify these changes, give their feedback on them, and respond accordingly. All of this must be done on one platform, in order to prevent any missed or misunderstood communication.

With real-time collaboration, hardware engineers/designers must be able to alter or develop a product with their complete focus, without having to go for time-consuming tasks like individually informing the rest of the stakeholders about their decisions. If they do have to resort to that, it breaks the lifecycle of the product and lead to inefficiency.

What is the solution?

The best way to tackle this issue is to have a single multi-stakeholder collaboration tool, which allows real-time changes and feedback. Such a tool will ensure that everyone is in the know about a product, and from engineers to distributors, can respond to any changes on a timely basis. In addition, it will ensure that feedback is shared in due time, so that it is incorporated accordingly.

What features must a good collaborative tool have?

When going for a collaborative tool, companies must keep their requirements in mind, and choose accordingly. However, any tool must have the following features:

- Version control

- Annotations

- Real-time change management

- Visual difference comparison

All of these features cater to both technical and non-technical members of the life cycle and put them on similar ground. This means that products are built in a more cohesive manner, and it is easier to strategize further.

In conclusion, real-time collaboration is essential for hardware companies. The most efficient way to achieve this is to have a single tool with all the features mentioned above, with the company’s budget for such things in mind. Once teams get to use the tool, productivity will go up at impressive rates!